LYNQ | MANUFACTURING EXECUTION (MES)

LYNQ is manufacturing execution software that connects seamlessly to your ERP to optimize you manufacturing workflows, automate data capture from machines/shopfloor, and provides world-class performance analysis and insights.

HIGHLIGHTS

Including finite capacity planning, overlapping operations, linking of subassemblies orders to parent orders, grouping of similar jobs and optimization routines. Real-Time Reporting

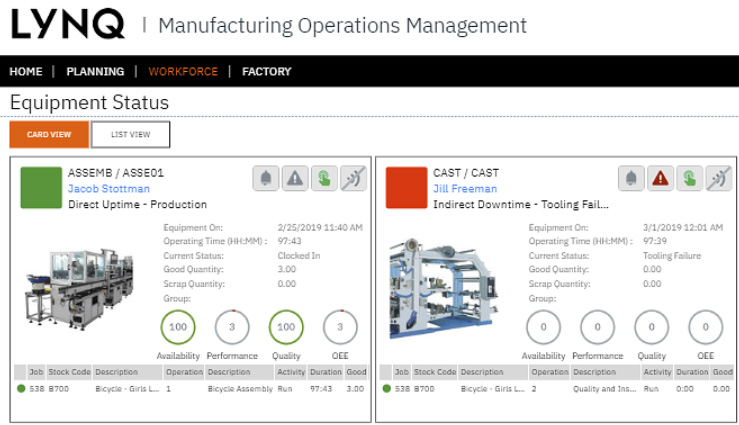

Real-time data collection and tracking of employees, equipment, and jobs. Automatic data capture from machines and other devices, connecting to 140+ industrial drivers.

World-class factory performance analysis with loss visualization. Dashboards and reports including order fulfilment, equipment utilization, and workforce dashboard.

BENEFITS

Resource management deals with the resources required to manufacture e.g., machines, tools, labor, and materials. Work units, tools, employee, and bill of material records. Resource Management is based on current and future requirements and performed in Enterprise Resource Planning and extended further within LYNQ to support operations management.

Detailed production scheduling optimizes the use of resources to meet production schedule requirements, taking into consideration resource and material availability The objective of detailed scheduling is to create and maintain a production plan and work schedules. Plan and prioritize operations to ensure maximum performance with minimal delay. Compare actual production to planned production. Reschedule the production plan and where schedules where work performance is not as expected, ensure delivery dates are not affected, where possible. Manage resource capacity. Simulate what-if scenarios to calculate production lead times. Provide effective management of bottleneck resources.

Execution management is the control of work through the sequence of operations as defined by the routing. Ensuring that tasks are released to the correct resources and performed within acceptable standards. Execution Management flows into data collection. The terminal feature can be used to build control into the manufacturing process. Terminals determine the functions that are available to a user for data collection and reporting purposes. The terminal definition represents a collection of predefined workbench elements which can be easily added or removed to suit the functions of your employees. Terminals are highly customizable and a flexible feature of LYNQ.

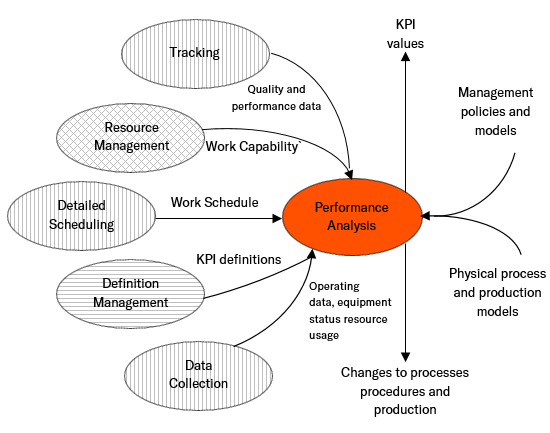

Performance analysis deals with the reporting of performance information and includes resource-based analysis such as overall labor effectiveness (OLE), overall equipment effectiveness (OEE), total effective equipment performance (TEEP) and product based analysis such as cycle times, procedural efficiencies and production variability. Performance analysis is visible in LYNQ with the exception of manufacturing cost analysis, which is obtained from Enterprise Resource Planning.

ADVANCED MES FOR ACUMATICA AND SAGE X3

DISCOVER MORE

- Lemay Nursery: Supporting Business Growth through LYNQ MES

- IKI Manufacturing: Cutting Inventory Costs by $4 Million in 6 months

- ACI Services: Saving Time and Digitalising Processes

- Watch how protective clothing manufacturer, Worldwide Protective Products, have used LYNQ MES to measure productivity and improve the efficiency of their manufacturing operations

Planning:

- Resource management

- Detailed scheduling

- Materials planning

- Capacity planning

- Online production plans

- Interactive job lists

Tracking:

- Job management

- Materials management

- Time and attendance

- Real-time tracking

- Performance monitoring

- Supervisory control

Automation:

- 140+ industrial device drivers (PLC/IO)

- Automatic data collection

- Human machine interface (HMI)

- Data management

Analysis:

- Factory performance (TEEP)

- Equipment performance (OEE)

- Employee performance (OLE)

- Product analysis

- Loss visualization

WHEREVER YOU ARE IN YOUR SOFTWARE JOURNEY, WE CAN HELP

We work with clients like you to explore your options, document your challenges, and implement the right solutions for your business. Fill out this form, and one of our Blytheco Solutions Specialists will reach out promptly.

I'm Looking For: